Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Optical Inspection of Microsystems: Exploring the Wonders of Optical Science and Engineering

The Fascinating World of Optical Inspection

When it comes to ensuring the quality and functionality of microsystems, optical inspection plays a crucial role. This powerful technique utilizes the principles of optical science and engineering to examine and analyze microstructures and detect any defects or issues that may hinder their performance. In this article, we will delve into the intricacies of optical inspection of microsystems and explore the exciting possibilities it brings to various industries.

Understanding Optical Science and Engineering

Optical science and engineering involve the manipulation and control of light to achieve desired outcomes. It encompasses the study of optics, the behavior of light, and the design and development of optical systems and devices. By harnessing the properties of light, optical engineers create innovative solutions for a wide range of applications, including optical inspection.

The Role of Optical Inspection in Microsystems

Microsystems, also known as microelectromechanical systems (MEMS),refer to miniaturized devices that combine mechanical and electrical components on a microscale. They are widely used in various industries, such as electronics, healthcare, automotive, aerospace, and telecommunications. Given their intricate nature, ensuring their quality and reliability is of utmost importance.

5 out of 5

| Language | : | English |

| File size | : | 45150 KB |

| Print length | : | 503 pages |

Optical inspection provides a non-destructive and efficient method for examining and evaluating microsystems. By using light-based techniques, it allows for the detection of defects, faults, and deviations in microstructures, ensuring the final product meets the desired specifications. Moreover, it enables manufacturers to conduct thorough quality control and perform failure analysis, leading to better overall product performance and customer satisfaction.

The Techniques Used in Optical Inspection

Optical inspection employs various techniques to examine microsystems at different stages of production. These techniques include:

- Microscopy: Optical microscopes are commonly used to visualize and inspect microstructures. They provide high-resolution imaging and allow for detailed analysis of the sample's features. Microscopes can be equipped with additional accessories like polarizers, interferometers, and fluorescence modules to enhance the inspection process.

- Confocal Imaging: Confocal microscopy is a powerful technique that improves image contrast and resolution. It selectively captures images at specific focal planes, eliminating out-of-focus background information. This enables precise imaging of complex microstructures and enhances defect detection.

- Interferometry: Interferometry is used to measure optical path differences and determine the surface characteristics of microsystems. By analyzing the interference patterns created by light waves, it can detect minute variations in height, shape, and dimensions. This technique is highly valuable in ensuring precise and accurate fabrication of microstructures.

- Holography: Holography utilizes the interference patterns created by light waves to reconstruct three-dimensional images. It provides a holistic view of microsystems, allowing engineers to inspect their entire structure and identify any potential flaws or discrepancies.

- Defect Inspection: Optical defect inspection techniques involve the use of specialized lighting and imaging setups to identify defects in microsystems. These defects can include cracks, scratches, contamination, or any other anomalies that may impair the functionality or reliability of the device. By detecting such issues early on, manufacturers can prevent costly failures and ensure consistent product quality.

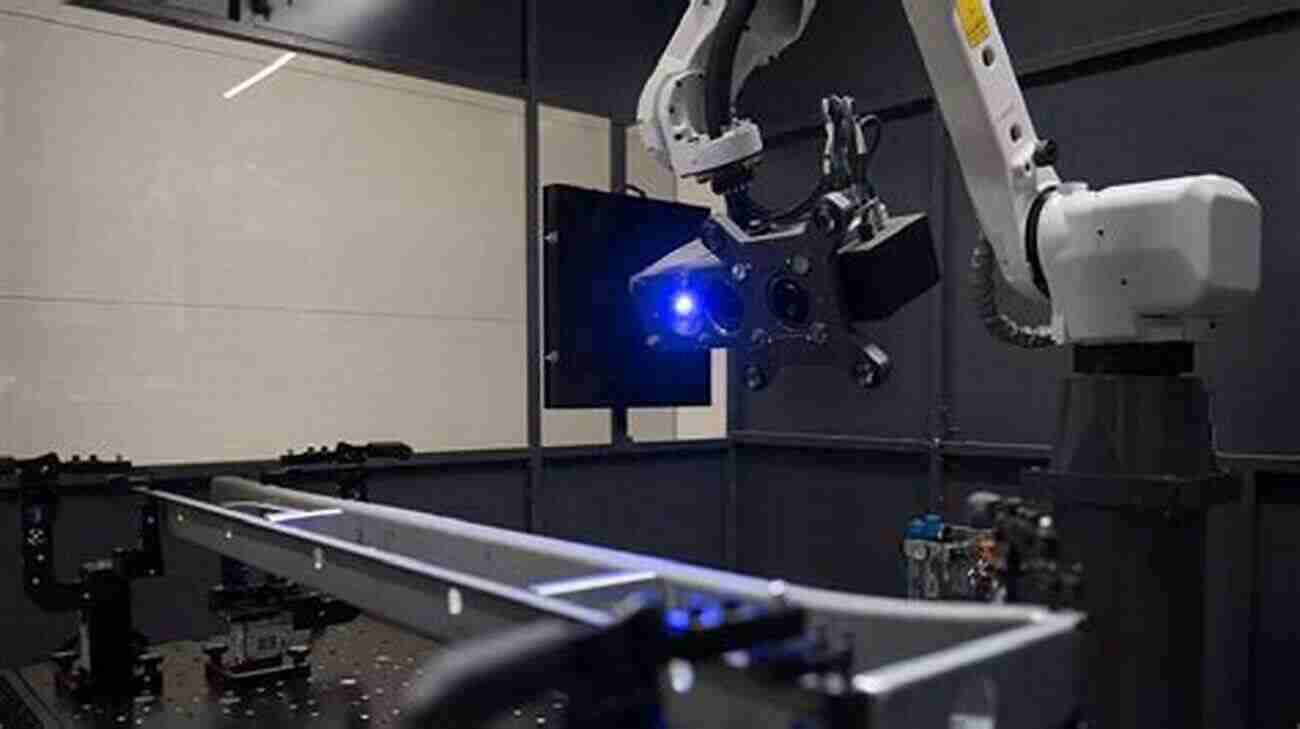

- Automated Optical Inspection (AOI): AOI systems integrate optics, image processing, and automation technologies to inspect microsystems rapidly. Using a combination of advanced algorithms and pattern recognition, AOI systems compare the captured images with reference templates, flagging any deviations or defects. This technique significantly improves inspection speed, accuracy, and repeatability, making it an invaluable tool in high-volume production environments.

Applications and Benefits

The applications of optical inspection in microsystems are vast and encompass numerous industries. Some notable examples include:

- Electronics: Optical inspection ensures the quality and reliability of integrated circuits, printed circuit boards (PCBs),and other electronic components. It is crucial in detecting defects like broken connections, damaged chips, or faulty solder joints.

- Healthcare and Biotechnology: Optical inspection is used in medical devices, such as pacemakers, biosensors, and diagnostic tools, ensuring their functionality and accuracy. It also aids in the examination of biological samples, such as cells and tissues, facilitating advanced research and diagnostics.

- Automotive: Microsystems play a significant role in automotive systems, including engine control units, airbag sensors, and tire pressure monitoring systems. Optical inspection guarantees the safety and reliability of these critical components.

- Aerospace and Defense: The aerospace industry relies on microsystems for various applications, such as navigation systems, sensors, and satellite components. Optical inspection ensures their proper functioning, durability, and adherence to strict quality standards.

- Telecommunications: Optical components, such as fiber optics, transceivers, and laser diodes, are essential in telecommunications networks. Optical inspection ensures high-performance and reliability of these components, leading to efficient data transfer and communication.

The benefits of optical inspection in microsystems are significant. By utilizing advanced imaging techniques, it allows for precise defect identification and characterization, resulting in improved product quality and reduced failure rates. It enhances manufacturing processes and facilitates rapid production throughput, ensuring efficient use of resources. Optical inspection also contributes to cost savings by preventing product recalls, minimizing rework, and avoiding potential liability issues.

The Future of Optical Inspection

The field of optical inspection is constantly evolving, driven by advancements in optical science, automation, and artificial intelligence. Emerging technologies, such as machine learning and computer vision, are being integrated into optical inspection systems, further enhancing their capabilities.

Future developments may include real-time defect recognition, autonomous inspection systems, and the integration of optical inspection with other quality control techniques. Additionally, the miniaturization of inspection tools and the development of compact, portable devices will allow for on-site inspection, benefitting industries that require remote or in-field inspections.

The optical inspection of microsystems is a fascinating field at the intersection of optical science and engineering. By using various techniques, it enables the examination, analysis, and quality control of microstructures, ensuring their performance and reliability. From electronics to healthcare, automotive, aerospace, and telecommunications, optical inspection plays a vital role in diverse industries, driving innovation and enabling technological advancements.

As the field continues to evolve, optical inspection techniques will become more sophisticated and automated, offering enhanced precision and efficiency. The future of optical inspection is poised to revolutionize manufacturing processes, lead to cost savings, and push the boundaries of what is possible in microsystem development.

5 out of 5

| Language | : | English |

| File size | : | 45150 KB |

| Print length | : | 503 pages |

Where conventional testing and inspection techniques fail at the micro-scale, optical techniques provide a fast, robust, and relatively inexpensive alternative for investigating the properties and quality of microsystems. Speed, reliability, and cost are critical factors in the continued scale-up of microsystems technology across many industries, and optical techniques are in a unique position to satisfy modern commercial and industrial demands.

Optical Inspection of Microsystems is the first comprehensive, up-to-date survey of the most important and widely used full-field optical metrology and inspection technologies. Under the guidance of accomplished researcher Wolfgang Osten, expert contributors from industrial and academic institutions around the world share their expertise and experience with techniques such as image correlation, light scattering, scanning probe microscopy, confocal microscopy, fringe projection, grid and moiré techniques, interference microscopy, laser Doppler vibrometry, holography, speckle metrology, and spectroscopy. They also examine modern approaches to data acquisition and processing. The book emphasizes the evaluation of various properties to increase reliability and promote a consistent approach to optical testing. Numerous practical examples and illustrations reinforce the concepts.

Supplying advanced tools for microsystem manufacturing and characterization, Optical Inspection of Microsystems enables you to reach toward a higher level of quality and reliability in modern micro-scale applications.

Fernando Pessoa

Fernando PessoaThe Ultimate Guide to New Addition Subtraction Games...

In this day and age, countless parents are...

Ethan Mitchell

Ethan MitchellThe Ultimate Guide for the Aspiring Pianist: Unleash Your...

Are you a beginner pianist feeling...

Gerald Parker

Gerald ParkerWow Robot Club Janice Gunstone - The Mastermind Behind...

Robots have always fascinated...

Dylan Hayes

Dylan HayesIdeal For Catching Up At Home: CGP KS2 Geography

Are you looking for the perfect resource to...

Kevin Turner

Kevin TurnerThe Ultimate Pictorial Travel Guide To Vietnam: Explore...

Discover the rich...

D'Angelo Carter

D'Angelo CarterUnlocking the Secrets of Compact Stars: Exploring...

Compact stars have...

Isaiah Price

Isaiah PriceUnveiling the Hidden Gem: Google Places Goliath Valley...

Are you tired of visiting the same old...

Donald Ward

Donald WardEssays Towards Theory Of Knowledge: Exploring the Depths...

Are you ready to delve into...

Thomas Mann

Thomas MannThe Ultimate PMP Project Management Professional All In...

Are you ready to take your project...

Trevor Bell

Trevor Bell10 Incredible Stories From Life In Football That Will...

The Beautiful Game - Football...

Zachary Cox

Zachary Cox100 Amazing And Unexpected Uses For Coconut Oil

Coconut oil, a versatile and widely loved...

Owen Simmons

Owen SimmonsUnveiling the Enigma of Die Blaue Brosche: A Family’s...

Have you ever heard of Die Blaue Brosche...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

George Bernard ShawSoviet Women Snipers on the Eastern Front 1941-45: Unleashing the Power of...

George Bernard ShawSoviet Women Snipers on the Eastern Front 1941-45: Unleashing the Power of...

Dustin RichardsonTeach Your Brilliant Family Dog To Catch, Fetch, Retrieve, Find And Bring...

Dustin RichardsonTeach Your Brilliant Family Dog To Catch, Fetch, Retrieve, Find And Bring... Ivan TurnerFollow ·2.6k

Ivan TurnerFollow ·2.6k Bryce FosterFollow ·10.2k

Bryce FosterFollow ·10.2k Leo TolstoyFollow ·5.8k

Leo TolstoyFollow ·5.8k Jaylen MitchellFollow ·5.2k

Jaylen MitchellFollow ·5.2k Peter CarterFollow ·17.9k

Peter CarterFollow ·17.9k Eli BrooksFollow ·8.4k

Eli BrooksFollow ·8.4k Damon HayesFollow ·3.1k

Damon HayesFollow ·3.1k Samuel BeckettFollow ·3.2k

Samuel BeckettFollow ·3.2k